Construction Features

The scale of HYWH construction works is massive and complicated. The project team has encountered many technical challenges during the works. With the excellent teamwork and the willingness for innovation and breakthrough, the project team has overcome various constraints with innovative ideas during the design and the construction.For example, the largest dual-mode Earth Pressure Balanced (EPB) Tunnel Boring Machine (TBM) in Hong Kong and first-ever 180-degree TBM U-turn operation were deployed in the construction of Lung Shan Tunnel, which shortened the construction time while enhanced the construction safety and efficiency.

The transportation of the TBM

Lung Shan Tunnel was excavated by a TBM with a diameter of 14.1 m, which is the largest dual-mode EPB TBM in Hong Kong. Since the major components of the TBM were huge, they had to be further dismantled into smaller pieces for transportation. However, the dismantled components were still about 3.5m to 7.5m wide, which had to be transported over two traffic lanes and at a low speed of 10 to 30km/h. To ensure safety, the transportation processes required the assistance and escort of the Police. In the early morning of April to August 2015, 61 pieces of large components were successfully transported from Tuen Mun Public Cargo Working Area to the tunnel construction site near Sha Tau Kok Road in 13 nights.

* Acknowledgement for the contractor to provide the film

TBM U-turn inside the cavern

The TBM weighed approximately 3,200 tonnes and was approximately 100m long. It was very technically challenging to turn this giant inside the tunnel without clashing with the cavern faces. The project team adopted a new and innovative technique.Firstly, the TBM was dismantled into 5 components, which were turned around one by one usinga huge horizontal turntable of 6m in diameter and 130 tonnes in weight, and re-assembled afterwards. The whole process took as long as three months. If the conventional way of dismantling, lifting and re–assembly of the TBM was adopted, the process would have taken about 6 months. Not only would such process delay the construction progress, but also affect the nearby traffic and environment. In contrast, adopting the state-of-the-art TBM U-turn technology had higher efficiency and saved more time. This technology was applied for the first time in Hong Kong and is rare elsewhere in the world.

* Acknowledgement for the contractor to provide the film

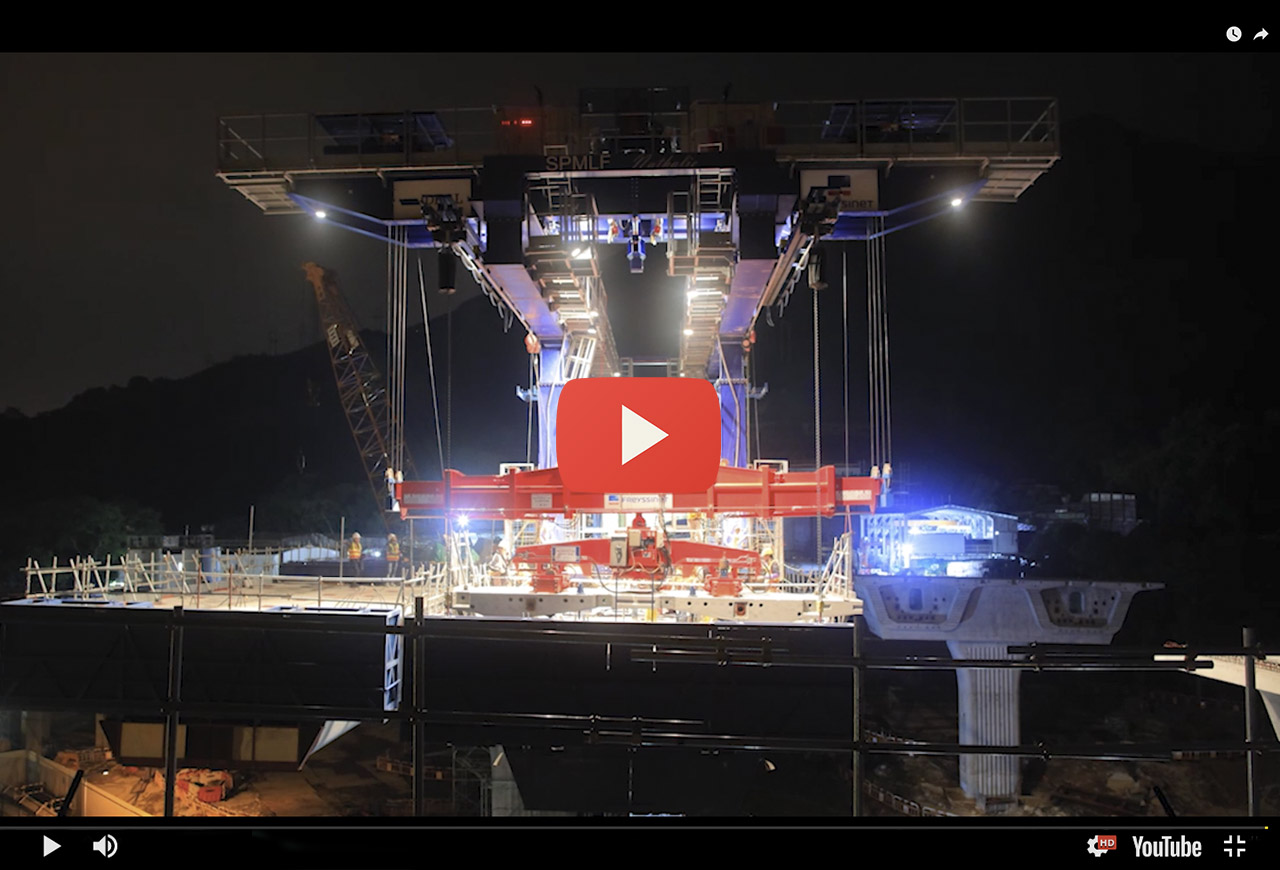

Precast Segment Installation of Viaduct at Fanling Highway Interchange

Some of the viaducts at the Fanling Highway Interchange span over the existing Fanling Highway and the MTR East Rail Line. Due to the safety reason and avoidance of disrupting the traffic, precast segment installation work at Fanling Highway Interchange over Fanling Highway and East Rail Line had to be carried out and completed after mid-night within a limited period of only two hours. During each installation, a tailor-made lifting frame has been adopted to ensure completion of the installation works precisely.

The project team maintained close communication with Hong Kong Police Force, Transport Department and Traffic and Transport Committee of District Council to liaise on the partial lane closure of Fanling Highway. In addition, when there was construction works above the East Rail Line, the project team had to work with the MTRafter the train services stopped at midnight to ensure no train service and electricity insulation fully implemented, completing the installation works within a limited period of two hours.The accurate coordination among all parties was required.

* Acknowledgement for the contractor to provide the film

* Acknowledgement for the contractor to provide the film

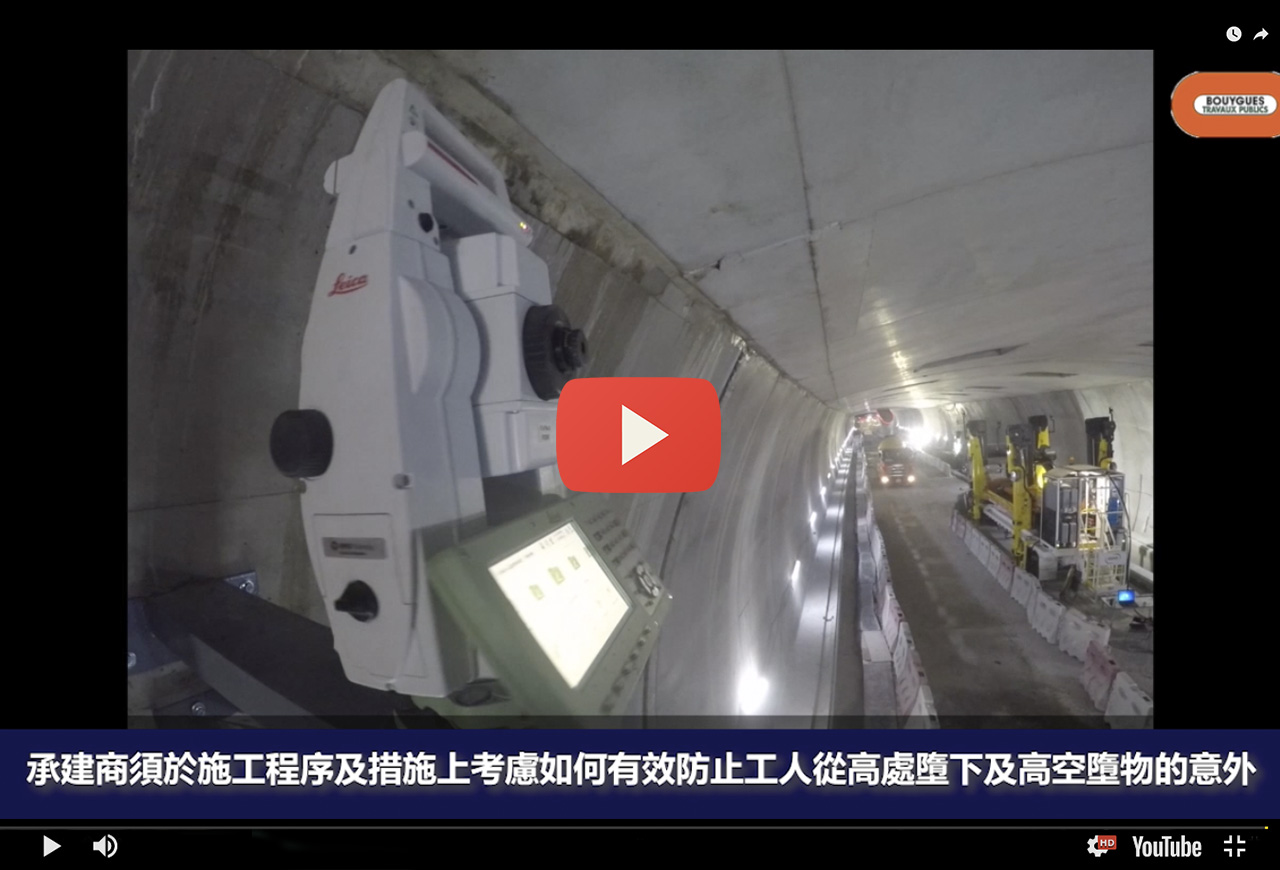

ROBY850 Semi-automatic Drilling Robot

In the construction works, working at height is one of the high risk activities. Contractors have to take into consideration in preparation of the construction sequences and measures how to effectively prevent workers and objects falling from heightDuring the tunnel construction, various E&M facilities are required to be fixed on the wall and slabs, and a large amount of anchor bolts have to be installed at height.In normal practice, workers have to stand on a working platform to drill each hole repeatedly by using a hand-held drill, which posed a high risk of workers and objects falling from height. In view of this situation, Dragages Hong Kong has designed a ROBY850 semi-automatic drilling robot to replace the need of labour. A robotic arm was installed on a lifting platform which was movable along tunnel after being mounted on a specific trailer. It was capable to complete the work in full process, including setting out, drilling, cleaning holes and installing anchors. As ROBY was a semi-automatic system, workers operated it from a safe location on the ground, hence reducing the risks of working at height.ROBY had an anchor magazine that stored 200 anchors. During the process of drilling, the distribution of the drill holes were accurately shown as 3D models on the monitor of ROBY. After drilling, ROBY cleaned the concrete dusts from the holes with pressured air.The program system of ROBY then automatically detected the diameter of the drills to select the right one, fetched the anchors, located the drill holes and performed the installation. ROBY had drastically enhanced the work efficiency while ensuring the workers’ safety.

* Acknowledgement for the contractor to provide the film